SALIENT FEATURES : |

|

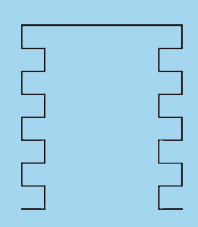

Freezing Lock System

Raksha uPVC Column Pipes have a unique ‘Freezing Lock’ type of locking system between the pipe and the coupler. This is specially designed for extra safety and versatility which does not allow the coupler to get detached from the pipe during installation and removal of pumps. This will also avoid column slippage during the operation of the system. This is applicable for all sizes ranging from 33mm (1”) to 140mm (5”) Outer Diameter.

Turbulence Free & Leak Proof Ring

Raksha Pipes are incorporated with specially designed Turbulence Free Ring in between the pipes inside the coupler, which fills the gap and prevent it from sudden expansion. It also observe the vibration cause due to high pump pressure. Therefore resulting in a smooth flow and more discharge of water with less energy consumption. The Ring is provided at the end of the threads which arrests total leakage. Combination of the above Turbulence Free Ring & Leak Proof Ring provides a 100% leak proof system and also enhances the thrust bearing & bush life of the pump set.

|

|

Square Threads

The coupler and pipe have square threads which are capable of taking high load with no slippage of threads. They can withstand the torque conditions created by the forward & reverse starting / stoppage of the motor.They are machined using special tools on CNC machine to maintain accurate dimensions for easy fitment. |

|

M.R.O. Technology

Raksha uses the highly acclaimed world class M.R.O. (Molecular Reorientation) technology for its column pipes manufacturing process. This highly proven technology produces the best quality pipes which resists fracture due to impact and survives in adverse operating conditions. Raksha combines this technology with its state of the art tool design which gives a perfect blend of product advantage wherein the pipes are produced to withstand the maximum high tensile load.

• PVC Pipe expanded in this manner becomes oriented, with enhanced mechanical property levels in the circumferential direction.

• The pipe is thus capable of sustaining greater hoop tensile stress without failure.

• The extrusion and orientation processes have been combined into a single operation.

• With this process theoretical strength is retained and zero percentage shrinkage

|

|

Retention of pipe strength :

Raksha ensures that pipe strength is not compromised due to the loss of material on account of threads. To compensate for loss of material due to threads the thickness of the pipe in the way of threads has been increased. Such a small increase for a limited length is provided to ensure not only smooth flow but also very negligible head loss. |

|

Display of Design Duty

Raksha is the only column pipe to display the designed duty in terms of “Water Head” and safe flow (LPS) on the ‘Head Load Capacity (Mtrs)’’and also mention the ‘Safe Flow (LPS)’ in each and every Pipe it manufactures. |

| |

|

Sr. |

Characteristic Features required for

Drop/ Riser Pipes

|

Features |

Galvanized Steel Pipes |

HDPE Pipes |

1 |

Rigidity |

Pipes are rigid |

Pipes are rigid |

Not rigid as compared to Column Pipe. Not right choice for Drop/Riser application as they tend to elongate & possibility of breakage is high

|

2 |

Load Carrying Capacity |

High Load Carrying Capacity due to inherent strength |

High Load Carrying Capacity due to heavy strength |

Less Load Carrying Capacity due to its flexibility. In the long run, with the heavy weight of the pump it elongates & breakage chances are more. |

3 |

More reliable threading joints. Anti rust and anti corrosion.

|

CNC machine cut square threads which are superior than any other to hold the weight without slippage. It is totally anti rust and anti corrosion for its entire life span. |

The threads have to be reworked after few years due to corrosion & rusting problem. The pipe length is reduced during this process as the customer has to cut the corroded portion of thread area. It involves additional expenses for the customer. |

Here it is only a normal & simple push type fitment with any fixture as the threading formulation is not possible due to its softness character. So the connection between the pipe & the pump is weak. |

4 |

Turbulence Free & Totally Leak Proof. |

Special design Turbulence Free Ring is provided to absorb the turbulence caused by pump pressure. Also high quality leak proof profile ring is provided to arrest total leakage. |

There is no total leak proof system provided. The threads are not pressure tight and does not have any rubber profile ring sealing. |

There is no selective method provided to absorb the turbulence. So wherever the pipe is weak in the entire column, cracks will occur and leakage is caused. Due to push type fitment between the fixture and the pipe it is prone to leak in the due course of time in that portion also. |

5 |

Low Frictional Loss |

Water discharge is more (10 to 30%) due to its special feature of smooth internal surface. Due to smooth internal surface the friction is low which results in low head loss. |

More head loss due to high friction and so discharge is affected. Friction is high due to rough Internal surface |

Over all discharge is less because the inner surface is not as smooth when compared to uPVC Column Pipes. |

6 |

Ease of Handling, Installation & Transportation. |

Pipes are of light weight which results in easy transportation, installation & removal. The length of each pipe is only 3 metres standard length and so that handling & fitment is easy |

Pipes are of heavy weight and come in 6 metres standard length which requires tedious efforts and more cautiousness for transportation, installation & removal even for lower depth bore wells. |

Comes in full length coil for the entire borewell length upto which it has to be installed. More chances of pipe damage during errection & lifting process. Rolling back after removal from bore well is also a very tedious job as it will become hard once used. |

7 |

Non Conductivity & Long Life Cycle. |

Pipes do not react with any acidic or alkaline substance in water. Hence replacement of pipes not required. Raksha Pipes have long life span up to 50 years |

Replacement of pipes required at regular intervals since it is prone to electro chemical reactions. Pipes are reactive to acidic and alkaline substances which reduces the life of the pipes. |

Thin walled HDPE pipes cannot be used for high pressure application in bore wells. They break away easily. When high thickness pipes are used for higher depth the discharge is reduced. |